Types of damage we can help you with.

For over fifteen years, the dedicated team at Glass Revived has been at the forefront of innovation in the glass restoration industry. Through extensive hands on testing and in depth evaluation of a wide variety of restoration tools, products, and techniques, we’ve come to a clear conclusion: there is no one size fits all solution for glass damage. Every situation is unique, requiring a tailored approach to achieve the best possible outcome.

In response to this need, we’ve developed an end to end process that covers every aspect of glass care including damage evaluation, professional restoration, long term protection, and preventative strategies. This comprehensive service is available to both domestic and commercial clients, ensuring that no matter the setting, your glass surfaces receive expert care and attention.

Our team brings a wealth of experience and specialised knowledge to every project. We handle all types of glass damage, from common issues such as hard water staining and chemical etching often found on household shower screens, to more complex restoration challenges like welding slag, acid damage, and angle grinder marks that affect commercial shopfronts and industrial settings. At Glass Revived, we are committed to delivering high quality, lasting results. We pride ourselves not only on our technical capabilities but also on our customer focused service. Whether you’re a homeowner looking to restore the clarity of your glass or a business needing a reliable restoration partner, we have the expertise, tools, and processes to meet your needs with precision and care.

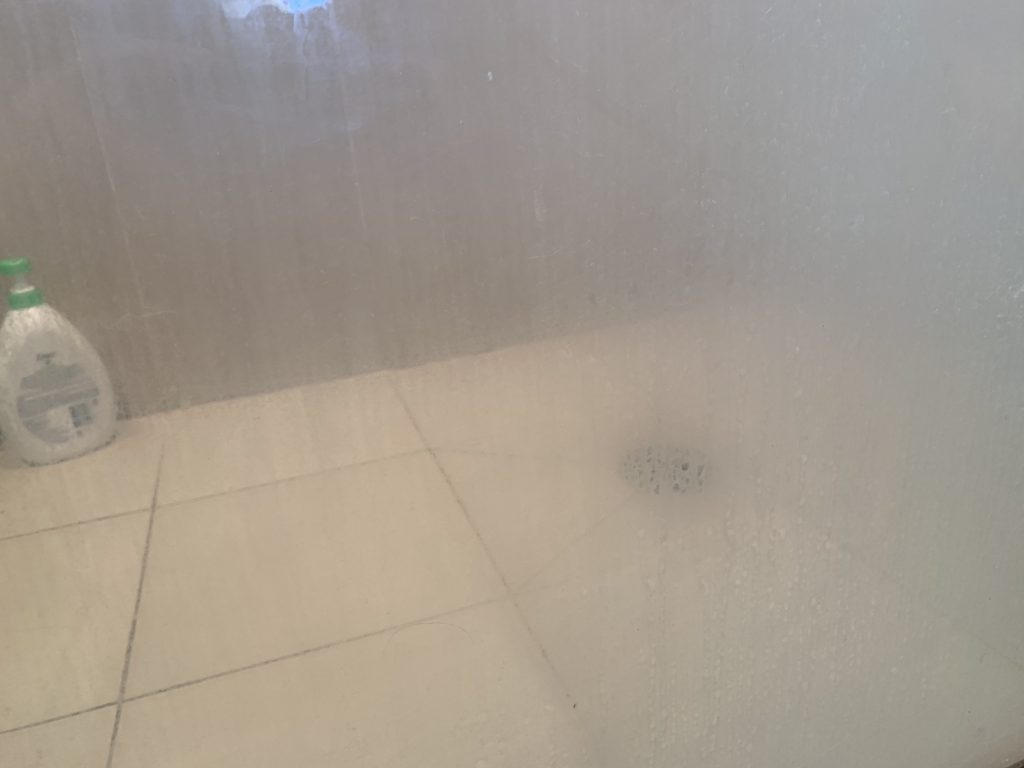

Hard water stains & etching

Hard water staining is a subtle yet persistent issue that occurs when dissolved minerals in water remain in prolonged contact with glass surfaces. Over time, especially under certain conditions, this leads to the buildup of mineral deposits that bond to the glass. A strong chemical interaction forms between the trace minerals in the glass and the residual minerals on the surface.

Hard water etching damages glass through mineral buildup. High concentrations of dissolved minerals adhere to the glass and cause erosion. These minerals bond with trace oxides, leading to surface deterioration. In some cases, etching can develop in as little as 12 to 18 months.

Chemical corrosion & etching

Chemical corrosion on glass, particularly on shower screens, is a gradual process where the surface of the glass deteriorates due to exposure to certain chemicals and minerals. Common causes include hard water deposits, high-pH or acidic cleaning products, and alkaline materials such as concrete dust. When these substances react with the glass especially in the presence of heat or poor rinsing, they can extract minerals like silica from the surface, leading to permanent damage. This often results in a cloudy, hazy, or frosted appearance that cannot be removed by regular cleaning. Over time, the corrosion not only affects the clarity of the glass but can also compromise its smoothness and overall appearance.

Metal oxide & concrete or cement etching

Both metal oxides and concrete or cement residue can etch glass—especially alkaline materials such as concrete wash-off. Concrete and cement contain high levels of lime, which is alkaline and can react with glass, causing etching. Additionally, substances released from concrete—such as certain cleaning agents—can also chemically attack glass surfaces.

The alkalinity of concrete and cement, combined with the presence of specific cleaning agents and metal oxides, contributes to etching and discolouration of glass.

Light and micro scratches

Light and micro scratches on glass can happen during construction, especially when materials like mortar, concrete, or render come into contact with the surface. Trying to scrub or scrape these materials off can leave anything from light marks to deep scratches. Even pets jumping at glass doors can cause minor scratching.

Abrasive cleaning tools, such as steel wool or rough sponges, can also damage glass. White sponges are usually safe, but green and blue sponges often leave fine, spiderweb-like scratches or swirling marks.

Deep scratching and graffiti

Heavy scratches on glass are deeper and more severe, often accompanied by chips or missing flecks along the edges. This damage is both visible and tactile, significantly affecting the glass’s appearance and structural integrity.

Due to the depth and severity, it’s important to thoroughly assess the deepest points before starting restoration. This helps determine the most effective repair method. Glass Revived uses specialised tools to remove both scratches and chips. By targeting the deepest marks, we can restore clarity while preserving the strength of the glass. The process is detailed and methodical to ensure no further harm occurs.

Acid-etched graffiti

Acid etch graffiti is a serious form of vandalism where strong acids, such as hydrofluoric acid, are used to burn markings into glass surfaces. These attacks leave behind permanent white, frosted designs or drip marks, often causing moderate to severe surface damage.

A detailed inspection is essential to assess the extent of the etching. Glass Revived use specialised tools and techniques to safely remove the damage, restoring clarity without compromising the strength or integrity of the glass. Timely treatment can prevent the need for full glass replacement and maintain the building’s appearance.

Angle grinder & welding marks

Damage from angle grinders and welding slag happens when hot metal sparks or molten particles come into contact with glass. This kind of damage is hard to repair and is usually only restored when glass replacement isn’t feasible.

If the glass is part of a building’s safety system—particularly if it’s tempered—extra caution is needed. Slag can break through the tempering layer or cause annealed glass to shatter.

These marks often trap metal particles in the glass. At Glass Revived, we carefully remove as much metal as possible before starting the repair. Trapped metal can overheat during restoration and expand rapidly, so precise planning and execution are essential to restore the glass safely and effectively.

Advanced glass protection that lasts

Today’s market offers a variety of glass coatings, most of which provide a basic hydrophobic layer that repels water. This helps reduce staining and makes cleaning easier—but these coatings typically last only 1 to 3 years, depending on environmental conditions, and require regular reapplication.

Discover Diamon-Fusion®: The ultimate glass coating

Diamon-Fusion® stands apart from conventional coatings. This patented technology chemically bonds with the glass surface to create a permanent, invisible barrier. The result? Enhanced durability and protection that transforms ordinary glass into a high-performance surface that resists stains, chips, and scratches.

Please refer to our partner links below for further information.